Product Description

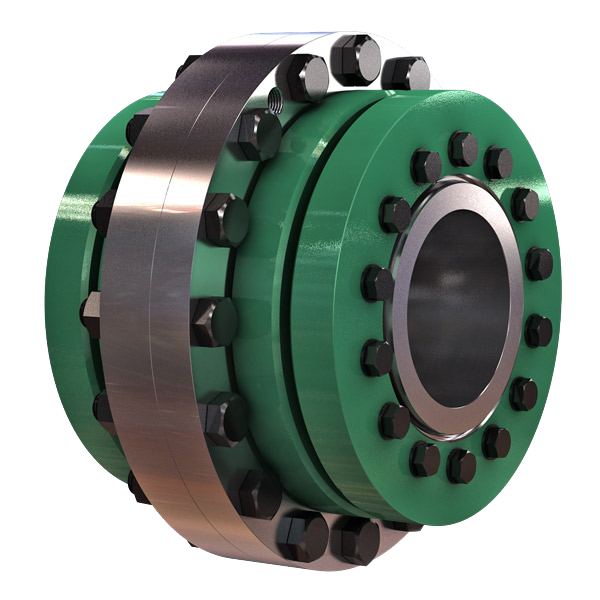

87943 87941 45 degree SAE FLANGE 9000 CHINAMFG hydraulic system coupling

Our Factory can make and supply as request size and type(quantity need).

For common types female fitting, male fitting, 45degree fitting, 90degree fitting,ferrule etc. All have stock.

If you want more details,sizes,datas about fitting,ferrule, please contact me. I will send you our catalogue.

Product Description

1. We keep improving our tech and have professional engineers to control the drawings

2. We always offer good quality for our clients with good price

3. We offer the best service in communication

4. We can carve client’s logo on the products, laser print

5. We can product complete same items based on client’s samples or drawings

6. We can provide FREE samples for test

| 87943 87941 45°SAE FLANGE 9000 PSI |

|||||||||

| PART NO. | FLANGE SIZE | HOSE BORE | DIMENSIONS | ||||||

| DN | DASH | A | C | D | H | L | |||

| 87943-12-12 | 3/4″ | 20 | 12 | 92.5 | 41.3 | 31.7 | 35.5 | 14.3 | |

| 87943-16-12 | 1″ | 20 | 12 | 93.5 | 47.6 | 38 | 36.5 | 14.3 | |

| 87943-16-16 | 1″ | 25 | 16 | 104 | 47.6 | 38 | 37.5 | 14.3 | |

| 87943-20-16 | 1.1/4″ | 25 | 16 | 104.5 | 54 | 43 | 38 | 14.3 | |

| 87943-20-20 | 1.1/4″ | 32 | 20 | 117 | 54 | 43 | 42 | 14.3 | |

| 87943-24-20 | 1.1/2″ | 32 | 20 | 118 | 63.5 | 50.8 | 43 | 14.3 | |

| 87943-24-24 | 1.1/2″ | 40 | 24 | 132.5 | 63.5 | 50.8 | 47 | 14.3 | |

Production step and test

All fitting and sleeves must passed strictly quality control:

Fitting Factory and warehouse

Factory showing and big fitting warehouse:

Fitting work different place

Fitting/flange/seelve/nipple for different equipments:

Other service hose machine

We also supply hose machine(hose crimping machine, hose cutting machine,hose skiving machine)hydraulic hose(R1/R2/R4/4SP/4SH/R14/R15/R9/R7/R8 etc. Welcome to contact and visit us for more details.

Packaging & Shipping

Good packing for protecting the products in long time delivery by sea or truck. Please check following:

Company and FAQ

HangZhou Qanmon Hydraulic Technology has always been committed to the research and development of Hydraulic hose and Tubing Processing Equipment, high and low pressure rubber hose, fitting joints etc.

History more than 20 years,export 12 years more, offering customized solutions gained from research, precision and quality.Now we professional team to sell, delivery, test and checking, sales after service. Guarranty clients can have good shopping service. Any questions, please contact me.

Welcome to visit my side at any time

FAQ:

Q: Are you trading company or manufacturer ?

A: We have own factory.

Q: How long is your delivery time?

A: Generally it is 2 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity finally.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A: stock products 100% payment before shipping out . In generally,30% deposit , 70% balance against B/L copy, L/C is also

acceptable. Other payment method is negotiable.

Q:Do you have hose and hose crimping machine?

Yes, we own factory to produce hose machine, for hose and fitting, we have cooperated factorys, boss has share.

So price and quality both can give you guarranty, and we can collect all together for you.

Supply other types hose:

1.Steel wire braided hydraulic hose

SAE 100 R1 AT / DIN EN853 1SN

SAE 100 R2 AT / DIN EN853 2SN

DIN EN857 1SC

DIN EN857 2SC

SAE 100 R16

SAE 100 R17

SAE 100 R5

2.Steel wire spiral hydraulic hose

DIN EN856 4SP

DIN EN856 4SH

SAE 100 R12

SAE 100 R13

SAE 100R15

3.Textile braided hydraulic hose

SAE 100 R3

SAE 100 R6

4.Rubber resin hose

SAE 100 R7 / DIN EN855 R7

SAE 100 R8 / DIN EN855 R8

5.Steam hose

Wire braided steam hose

6.PTFE Hose

SAE 100 R14 /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Flange Couplings in Corrosive or Harsh Environments

Flange couplings can be used in a wide range of environments, including corrosive or harsh conditions, depending on the material and coating used in their construction. The choice of material is a critical factor in determining the suitability of a flange coupling for such environments.

Materials:

Stainless steel flange couplings are commonly used in corrosive environments due to their high resistance to rust and corrosion. Stainless steel contains chromium, which forms a protective oxide layer on the surface, preventing the underlying metal from being exposed to corrosive elements.

In particularly aggressive or chemically harsh environments, super alloys or specialty materials like Hastelloy or Inconel may be used for flange couplings, providing even higher corrosion resistance and chemical stability.

Coatings:

In addition to material selection, certain coatings can further enhance the resistance of flange couplings to corrosive environments. For example, coatings like zinc plating or epoxy coatings can add an extra layer of protection against corrosion.

Sealing and Protection:

Flange couplings used in harsh environments may also incorporate specialized sealing elements to prevent the ingress of contaminants, moisture, or corrosive substances. Proper sealing can significantly extend the service life of the coupling and the connected equipment.

Regular Maintenance:

While flange couplings designed for harsh environments are built to withstand corrosive elements, regular maintenance is essential to ensure their optimal performance. Regular inspections, cleaning, and lubrication, as well as prompt replacement of any damaged components, are vital to maintaining the integrity and functionality of the coupling.

Application Considerations:

When using flange couplings in corrosive or harsh environments, it is essential to consider the specific requirements of the application. Factors such as the type and concentration of corrosive substances, temperature variations, and mechanical loads should be carefully assessed to select the most suitable flange coupling for the given environment.

Conclusion:

Flange couplings can be engineered to withstand corrosive and harsh environments by using appropriate materials, coatings, and sealing techniques. With proper selection, installation, and maintenance, flange couplings can provide reliable and durable performance in challenging industrial settings.

Can Flange Couplings Be Used in Food Processing and Pharmaceutical Industries?

Yes, flange couplings can be used in food processing and pharmaceutical industries, provided they meet certain requirements and standards to ensure hygiene and product safety. These industries have stringent regulations and guidelines to prevent contamination and maintain the quality and purity of their products. When selecting flange couplings for such applications, several considerations must be taken into account:

- Material Selection: The flange coupling material must be food-grade or pharmaceutical-grade and comply with industry-specific regulations. Stainless steel, particularly austenitic grades like 316L, is commonly used due to its excellent corrosion resistance and ease of cleaning.

- Hygienic Design: Flange couplings for these industries should have a hygienic design that minimizes crevices, dead spaces, and surface roughness where bacteria or contaminants could accumulate. Smooth surfaces and seamless construction help facilitate thorough cleaning and sterilization.

- Sealing and Lubrication: Proper sealing is essential to prevent any potential leaks or ingress of contaminants. Food-grade or pharmaceutical-grade lubricants should be used to ensure that there is no risk of contamination from the coupling’s lubrication.

- Certifications and Compliance: Flange couplings intended for use in food processing and pharmaceutical industries should have relevant certifications, such as FDA (U.S. Food and Drug Administration) approval, EU regulations (e.g., EC No. 1935/2004), and compliance with industry standards like 3-A Sanitary Standards.

- Cleanability: Flange couplings should be designed for easy disassembly and cleaning to maintain the required hygiene standards. This may involve quick-release or tool-less designs that allow for frequent inspection and cleaning without impeding production processes.

- Resistant to Corrosive Cleaning Agents: In food processing and pharmaceutical industries, aggressive cleaning agents may be used. The flange coupling material should be resistant to these substances to avoid degradation and maintain the coupling’s integrity over time.

By meeting these criteria, flange couplings can be safely used in food processing and pharmaceutical applications without compromising product quality or safety. It is crucial to work with reputable manufacturers or suppliers who understand the specific requirements of these industries and can provide couplings that adhere to the necessary standards.

How Do Flange Couplings Compare to Other Types of Couplings in Terms of Performance?

Flange couplings offer several advantages and disadvantages compared to other types of couplings, and their performance depends on the specific requirements of the application. Here’s a comparison of flange couplings with other common coupling types:

1. Flexible Couplings:– Misalignment Handling: Flexible couplings, such as elastomeric or jaw couplings, excel in handling shaft misalignment, both angular and axial. Flange couplings have limited misalignment accommodation compared to flexible couplings.- Vibration Damping: Flexible couplings can absorb and dampen vibrations, reducing the impact on connected equipment. Flange couplings, being rigid, provide less vibration dampening.- Load Capacity: Flange couplings can handle higher torque and loads due to their rigid design, making them suitable for heavy-duty applications. Flexible couplings have a lower torque and load capacity but offer other benefits.2. Gear Couplings:– Misalignment Handling: Gear couplings are capable of handling higher levels of misalignment, especially angular misalignment.- Load Capacity: Gear couplings are robust and can transmit high torque and handle heavy loads similar to flange couplings.- Complexity: Gear couplings have a more intricate design compared to flange couplings, which may result in higher manufacturing costs.3. Disc Couplings:– Misalignment Handling: Disc couplings can accommodate moderate misalignment, but they are not as effective as flexible couplings in this aspect.- Torsional Stiffness: Disc couplings offer high torsional stiffness, making them suitable for precise motion control applications.- Temperature Resistance: Disc couplings can withstand higher operating temperatures compared to some other coupling types.4. Fluid Couplings:– Slip Capability: Fluid couplings provide slip between input and output, allowing for smoother starts and reduced shock loads during acceleration.- Efficiency: Fluid couplings may introduce power losses due to fluid shear, resulting in lower efficiency compared to some other coupling types.In summary, flange couplings are ideal for applications requiring high torque transmission and rigid shaft connections. They are commonly used in industrial machinery, pumps, and compressors. However, for applications with misalignment issues, vibration concerns, or the need for torsional flexibility, other coupling types like flexible couplings or gear couplings might be more suitable. The choice of coupling depends on factors such as the specific application, misalignment, load requirements, and the desired level of vibration isolation or damping needed in the system.

editor by CX 2024-04-04