Product Description

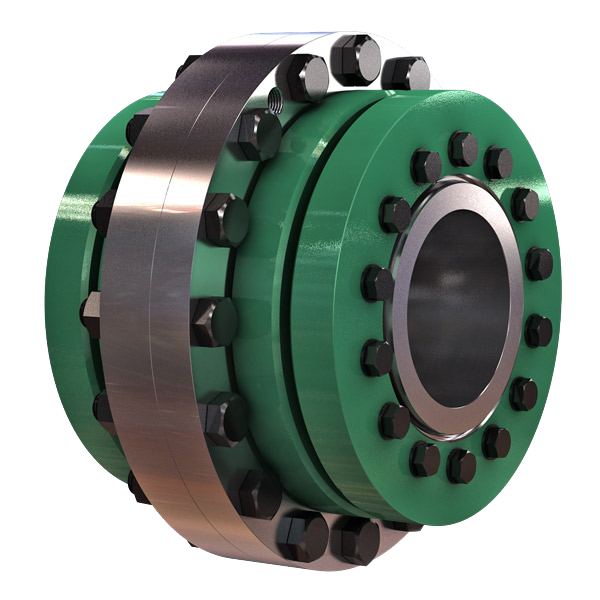

NHF Hydraulic Safety Coupling With Flange

Description of NHF Hydraulic Safety Coupling With Flange

1.Simple and convenient assembly and disassembly;

2.No keyway and thrust ring are required on the shaft;

3.The stress on the entire contact surface is relatively uniform, and the stress concentration is not obvious;

4.When the vibration load of the shaft system changes, the shaft will not be worn;

5.The position of the coupling on the shaft is easy to ensure, and the connection accuracy is high;

6.Can be used repeatedly, with high interchangeability.

Dimensions of NHF Hydraulic Safety Coupling With Flange

|

|

d |

D |

L |

L1 |

Df |

Dc |

R |

t |

n |

ds |

Mt |

Mass |

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kNm |

kg |

||

|

NHF100 |

100 |

170 |

215 |

40 |

265 |

230 |

9 |

21 |

8 |

19 |

26 |

26 |

|

NHF110 |

110 |

186 |

235 |

45 |

295 |

255 |

10 |

23 |

8 |

21 |

35 |

34 |

|

NHF120 |

120 |

202 |

250 |

50 |

315 |

275 |

11 |

25 |

8 |

23 |

46 |

42 |

|

NHF130 |

130 |

218 |

270 |

55 |

340 |

295 |

11 |

27 |

8 |

25 |

58 |

52 |

|

NHF140 |

140 |

234 |

290 |

60 |

355 |

310 |

12 |

29 |

10 |

24 |

72 |

64 |

|

NHF150 |

150 |

250 |

300 |

60 |

380 |

335 |

13 |

31 |

10 |

26 |

89 |

75 |

|

NHF160 |

160 |

266 |

320 |

65 |

405 |

355 |

14 |

33 |

10 |

28 |

108 |

91 |

|

NHF170 |

170 |

282 |

340 |

70 |

430 |

375 |

15 |

35 |

10 |

30 |

130 |

108 |

|

NHF180 |

180 |

298 |

355 |

75 |

440 |

390 |

15 |

37 |

12 |

29 |

154 |

124 |

|

NHF190 |

190 |

314 |

375 |

80 |

465 |

410 |

16 |

39 |

12 |

30 |

181 |

145 |

|

NHF200 |

200 |

330 |

390 |

80 |

490 |

435 |

17 |

41 |

12 |

32 |

211 |

167 |

|

NHF210 |

210 |

346 |

410 |

85 |

515 |

455 |

18 |

43 |

12 |

33 |

244 |

193 |

|

NHF220 |

220 |

362 |

425 |

90 |

535 |

475 |

19 |

45 |

12 |

35 |

281 |

219 |

|

NHF230 |

230 |

378 |

445 |

95 |

560 |

495 |

19 |

47 |

12 |

37 |

321 |

249 |

|

NHF240 |

240 |

394 |

465 |

100 |

580 |

515 |

20 |

49 |

12 |

38 |

365 |

282 |

|

NHF250 |

250 |

410 |

475 |

100 |

605 |

535 |

21 |

51 |

12 |

40 |

412 |

313 |

|

NHF260 |

260 |

426 |

495 |

105 |

630 |

560 |

22 |

53 |

12 |

42 |

464 |

352 |

|

NHF270 |

270 |

442 |

515 |

110 |

655 |

580 |

23 |

55 |

12 |

43 |

519 |

394 |

|

NHF280 |

280 |

458 |

530 |

115 |

675 |

600 |

23 |

57 |

12 |

45 |

579 |

434 |

|

NHF290 |

290 |

474 |

550 |

120 |

700 |

620 |

24 |

59 |

12 |

46 |

644 |

483 |

|

NHF300 |

300 |

490 |

565 |

120 |

720 |

640 |

25 |

61 |

12 |

48 |

713 |

528 |

|

NHF310 |

310 |

506 |

580 |

125 |

750 |

665 |

26 |

63 |

12 |

50 |

786 |

582 |

|

NHF320 |

320 |

522 |

600 |

130 |

770 |

685 |

27 |

65 |

12 |

51 |

865 |

638 |

|

NHF330 |

330 |

538 |

620 |

135 |

795 |

705 |

27 |

67 |

12 |

53 |

948 |

700 |

|

NHF340 |

340 |

554 |

635 |

140 |

815 |

725 |

28 |

69 |

12 |

54 |

1037 |

759 |

|

NHF350 |

350 |

570 |

650 |

140 |

840 |

745 |

29 |

71 |

12 |

56 |

1131 |

823 |

|

NHF360 |

360 |

586 |

670 |

145 |

835 |

750 |

30 |

73 |

16 |

50 |

1231 |

878 |

|

|

d |

D |

L |

L1 |

Df |

Dc |

R |

t |

n |

ds |

Mt |

Mass |

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kNm |

kg |

||

|

NHF370 |

370 |

602 |

690 |

150 |

855 |

770 |

31 |

75 |

16 |

51 |

1337 |

951 |

|

NHF380 |

380 |

618 |

705 |

155 |

880 |

790 |

31 |

77 |

16 |

53 |

1448 |

1026 |

|

NHF390 |

390 |

634 |

725 |

160 |

900 |

810 |

32 |

79 |

16 |

54 |

1565 |

1108 |

|

NHF400 |

400 |

650 |

740 |

160 |

930 |

835 |

33 |

81 |

16 |

56 |

1689 |

1194 |

|

NHF410 |

410 |

666 |

755 |

165 |

950 |

855 |

34 |

83 |

16 |

57 |

1819 |

1277 |

|

NHF420 |

420 |

682 |

775 |

170 |

975 |

875 |

35 |

85 |

16 |

58 |

1955 |

1376 |

|

NHF430 |

430 |

698 |

795 |

175 |

995 |

895 |

35 |

87 |

16 |

60 |

2098 |

1474 |

|

NHF440 |

440 |

714 |

810 |

180 |

1571 |

915 |

36 |

89 |

16 |

61 |

2248 |

1574 |

|

NHF450 |

450 |

730 |

825 |

180 |

1040 |

935 |

37 |

91 |

16 |

63 |

2405 |

1674 |

|

NHF460 |

460 |

746 |

845 |

185 |

1060 |

955 |

38 |

93 |

16 |

64 |

2569 |

1787 |

|

NHF470 |

470 |

762 |

860 |

190 |

1085 |

975 |

39 |

95 |

16 |

65 |

2740 |

1900 |

|

NHF480 |

480 |

778 |

880 |

195 |

1105 |

995 |

39 |

97 |

16 |

67 |

2918 |

2571 |

|

NHF490 |

490 |

794 |

900 |

200 |

1130 |

1015 |

40 |

99 |

16 |

68 |

3105 |

2156 |

|

NHF500 |

500 |

810 |

910 |

200 |

1150 |

1035 |

41 |

101 |

16 |

70 |

3299 |

2267 |

|

NHF510 |

510 |

826 |

930 |

205 |

1175 |

1055 |

42 |

103 |

16 |

71 |

3501 |

2411 |

|

NHF520 |

520 |

842 |

950 |

210 |

1195 |

1075 |

43 |

105 |

16 |

72 |

3711 |

2554 |

|

NHF530 |

530 |

858 |

965 |

215 |

1220 |

1095 |

43 |

107 |

16 |

74 |

3929 |

2698 |

|

NHF540 |

540 |

874 |

985 |

220 |

1240 |

1115 |

44 |

109 |

16 |

75 |

4155 |

2852 |

|

NHF550 |

550 |

890 |

1000 |

220 |

1270 |

1140 |

45 |

111 |

16 |

77 |

4391 |

3014 |

|

NHF560 |

560 |

906 |

1571 |

225 |

1290 |

1160 |

46 |

113 |

16 |

78 |

4634 |

3180 |

|

NHF570 |

570 |

922 |

1035 |

230 |

1310 |

1180 |

47 |

115 |

16 |

79 |

4887 |

3338 |

|

NHF580 |

580 |

938 |

1055 |

235 |

1335 |

1200 |

47 |

117 |

16 |

81 |

5149 |

3524 |

|

NHF590 |

590 |

954 |

1075 |

240 |

1355 |

1220 |

48 |

119 |

16 |

82 |

5420 |

3708 |

|

NHF600 |

600 |

970 |

1085 |

240 |

1380 |

1240 |

49 |

121 |

16 |

84 |

5700 |

3877 |

|

NHF610 |

610 |

986 |

1105 |

245 |

1400 |

1260 |

50 |

123 |

16 |

85 |

5990 |

4072 |

|

NHF620 |

620 |

1002 |

1125 |

250 |

1425 |

1280 |

51 |

125 |

16 |

86 |

6289 |

4284 |

|

NHF630 |

630 |

1018 |

1140 |

255 |

1445 |

1300 |

51 |

127 |

16 |

88 |

6599 |

4477 |

|

NHF640 |

640 |

1034 |

1160 |

260 |

1465 |

1320 |

52 |

129 |

16 |

89 |

6918 |

4692 |

|

NHF650 |

650 |

1050 |

1175 |

260 |

1495 |

1345 |

53 |

131 |

16 |

91 |

7247 |

4917 |

|

NHF660 |

660 |

1066 |

1190 |

265 |

1515 |

1365 |

54 |

133 |

16 |

92 |

7587 |

5128 |

|

NHF670 |

670 |

1082 |

1210 |

270 |

1540 |

1385 |

55 |

135 |

16 |

93 |

7937 |

5375 |

|

NHF680 |

680 |

1098 |

1230 |

275 |

1560 |

1405 |

55 |

137 |

16 |

95 |

8298 |

5618 |

|

NHF690 |

690 |

1114 |

1245 |

280 |

1585 |

1425 |

56 |

139 |

16 |

96 |

8669 |

5860 |

|

NHF700 |

700 |

1130 |

1260 |

280 |

1605 |

1445 |

57 |

141 |

16 |

98 |

9052 |

6097 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Impact of Flange Coupling on the Overall Reliability of Connected Equipment

A flange coupling plays a crucial role in ensuring the overall reliability and performance of connected equipment in a mechanical system. Its impact can be summarized as follows:

- 1. Power Transmission Efficiency: Flange couplings provide a secure and rigid connection between shafts, enabling efficient power transmission from one component to another. By minimizing energy losses through slippage or vibration, flange couplings help maintain the overall efficiency of the system.

- 2. Reducing Wear and Tear: Flange couplings accommodate misalignment and slight axial movement, reducing stress on connected equipment. By absorbing shocks and vibrations, they protect the components from excessive wear and fatigue, increasing their lifespan.

- 3. Controlling Vibration and Noise: A properly selected and installed flange coupling helps dampen vibrations and reduces noise levels in the system. This is particularly important in precision machinery, where vibrations can affect the accuracy and performance of the equipment.

- 4. Handling Misalignment: Flange couplings can compensate for angular, parallel, and axial misalignment between shafts. This capability ensures smooth operation and prevents excessive forces that could lead to premature failure of equipment components.

- 5. Improving System Flexibility: Flange couplings offer flexibility in design and installation. They allow for quick and easy disconnection and reconnection of equipment for maintenance or repairs, minimizing downtime and increasing the system’s overall availability.

- 6. Protection Against Overloads: In high-torque applications, flange couplings provide a safeguard against overloads by slipping or disengaging when the torque exceeds the coupling’s capacity. This helps prevent damage to the equipment and ensures the safety of the system and operators.

- 7. Corrosion Resistance: Depending on the material selected, flange couplings can offer excellent corrosion resistance, making them suitable for use in harsh environments or corrosive conditions. This protects the connected equipment from premature deterioration.

- 8. Maintenance and Downtime Reduction: The reliability of flange couplings leads to reduced maintenance needs and less frequent downtime. A well-maintained coupling can significantly extend the life of connected equipment and reduce the frequency of replacements or repairs.

- 9. Enhancing System Safety: Flange couplings provide a secure connection that ensures the safe operation of rotating machinery. They minimize the risk of unexpected equipment failure or disconnection, promoting the safety of operators and surrounding personnel.

- 10. Adaptability to Different Industries: Flange couplings are widely used across various industries, from manufacturing and power generation to mining and aerospace. Their versatility and reliability make them suitable for a wide range of applications, contributing to the overall success and efficiency of these industries.

In conclusion, the proper selection and use of flange couplings significantly impact the overall reliability and performance of connected equipment. Their ability to transmit power efficiently, handle misalignment, and protect against wear and overloads ensures smooth and safe operation, reducing maintenance costs, and increasing the lifespan of machinery.

Can Flange Couplings Be Used in Food Processing and Pharmaceutical Industries?

Yes, flange couplings can be used in food processing and pharmaceutical industries, provided they meet certain requirements and standards to ensure hygiene and product safety. These industries have stringent regulations and guidelines to prevent contamination and maintain the quality and purity of their products. When selecting flange couplings for such applications, several considerations must be taken into account:

- Material Selection: The flange coupling material must be food-grade or pharmaceutical-grade and comply with industry-specific regulations. Stainless steel, particularly austenitic grades like 316L, is commonly used due to its excellent corrosion resistance and ease of cleaning.

- Hygienic Design: Flange couplings for these industries should have a hygienic design that minimizes crevices, dead spaces, and surface roughness where bacteria or contaminants could accumulate. Smooth surfaces and seamless construction help facilitate thorough cleaning and sterilization.

- Sealing and Lubrication: Proper sealing is essential to prevent any potential leaks or ingress of contaminants. Food-grade or pharmaceutical-grade lubricants should be used to ensure that there is no risk of contamination from the coupling’s lubrication.

- Certifications and Compliance: Flange couplings intended for use in food processing and pharmaceutical industries should have relevant certifications, such as FDA (U.S. Food and Drug Administration) approval, EU regulations (e.g., EC No. 1935/2004), and compliance with industry standards like 3-A Sanitary Standards.

- Cleanability: Flange couplings should be designed for easy disassembly and cleaning to maintain the required hygiene standards. This may involve quick-release or tool-less designs that allow for frequent inspection and cleaning without impeding production processes.

- Resistant to Corrosive Cleaning Agents: In food processing and pharmaceutical industries, aggressive cleaning agents may be used. The flange coupling material should be resistant to these substances to avoid degradation and maintain the coupling’s integrity over time.

By meeting these criteria, flange couplings can be safely used in food processing and pharmaceutical applications without compromising product quality or safety. It is crucial to work with reputable manufacturers or suppliers who understand the specific requirements of these industries and can provide couplings that adhere to the necessary standards.

Can Flange Couplings Accommodate High Torque and High-Speed Applications?

Yes, flange couplings are designed to accommodate both high torque and high-speed applications. They are capable of transmitting significant amounts of torque between shafts while maintaining stable and efficient power transmission. The ability to handle high torque and high-speed applications depends on various factors, including the design, material, and size of the flange coupling.

1. Design: Flange couplings are available in different designs, such as rigid flange couplings and flexible flange couplings. Rigid flange couplings are more suitable for applications that require precise shaft alignment and minimal misalignment. On the other hand, flexible flange couplings can accommodate slight misalignments and are suitable for applications where shock or vibration may occur. The design of the coupling is crucial in determining its torque and speed capabilities.

2. Material: Flange couplings are manufactured from various materials, including steel, stainless steel, aluminum, and other alloys. The material selection is essential in determining the coupling’s strength, durability, and resistance to wear and fatigue. High-quality materials are used in flange couplings for high torque and high-speed applications to ensure their reliability and performance.

3. Size and Dimensions: The size and dimensions of the flange coupling play a significant role in determining its torque and speed ratings. Larger flange couplings with increased diameter and thickness can handle higher torque and speed compared to smaller couplings. It is essential to choose the appropriate size of the coupling based on the application’s torque and speed requirements.

4. Surface Finish: The surface finish of the flange coupling is critical, especially in high-speed applications. A smooth surface finish reduces friction and wear between the mating surfaces of the flanges, bolts, and nuts, thereby improving the overall efficiency of the coupling.

5. Lubrication: Proper lubrication is essential for flange couplings in high-speed and high-torque applications. Lubricants help reduce friction and wear, dissipate heat, and prevent premature failure of the coupling components.

6. Manufacturer’s Recommendations: It is crucial to follow the manufacturer’s recommendations and guidelines regarding the maximum torque and speed ratings of the flange coupling. Exceeding the recommended limits can lead to coupling failure and potential damage to the connected equipment.

In conclusion, flange couplings can be effectively used in high torque and high-speed applications when selected and maintained properly. Choosing the right design, material, size, and adhering to the manufacturer’s guidelines ensures that the flange coupling can handle the required torque and rotational speed efficiently and reliably.

editor by CX 2024-03-30